In the competitive landscape of solar energy, project margins are perpetually under pressure. The drive to reduce Capital Expenditure (CAPEX) is a dominant factor in procurement. This often leads developers and EPCs to scrutinize every line item, with solar mounting structures (MMS) being a frequent target for cost-cutting.

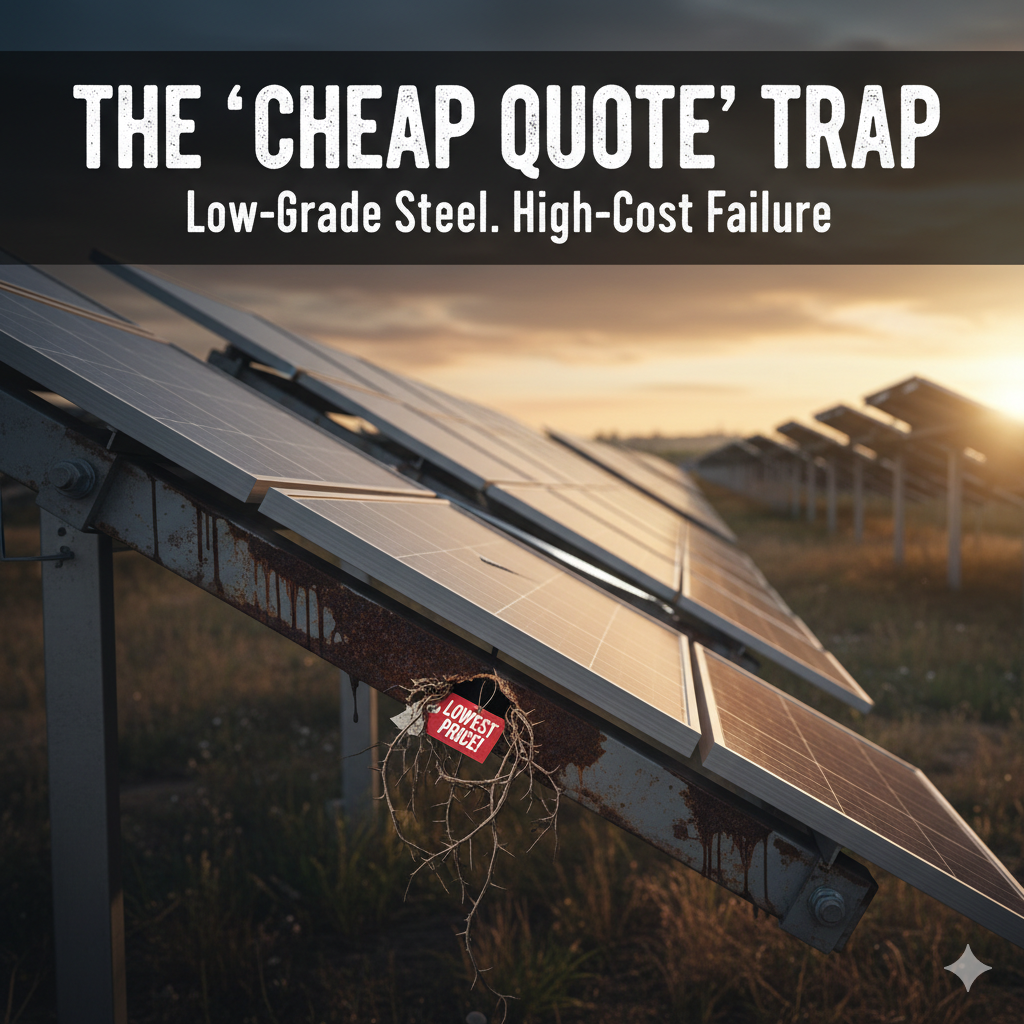

However, opting for a “cheap quote” on this critical component is a profound, and often irreversible, strategic error.

This decision, seemingly a minor CAPEX saving, directly introduces material risk, increases long-term Operational Expenditure (OPEX), and can ultimately threaten the 25-year viability and bankability of the entire asset.

This article analyzes the technical and financial impacts of using low-grade steel and substandard fabrication in your solar projects.

The Anatomy of a “Cheap” Structure

A significantly lower quote is not a sign of efficiency; it is a declaration of compromise. This compromise is almost always made in two areas:

- Material Specifications: The manufacturer substitutes specified, high-grade steel from reputable mills with lower-grade, non-certified, or thinner-gauge materials. This also applies to the galvanization, where a thinner, less-adherent zinc coating is used, drastically reducing corrosion resistance.

- Engineering & Design Verification: The manufacturer skips the crucial step of “design verification.” Instead of engineering a solution for your project’s specific panel model and wind-load requirements, they provide a “standard,” one-size-fits-all product.

These compromises are the source of severe downstream consequences.

Immediate Impact: Project Execution and Commissioning

The financial damage begins the moment the materials arrive on-site.

The most common issue is panel-to-structure incompatibility. Because the low-cost supplier skipped the design verification, the mounting holes on their “standard” structure do not align with your chosen solar panels.

This single oversight creates a cascade of costly problems:

- On-Site Fabrication: Your installation team is forced to drill new holes or make other crude modifications on-site. This non-standard work is slow, expensive, and immediately voids material warranties.

- Compromised Integrity: Drilling new holes on a galvanized structure shatters the protective zinc coating, creating an immediate entry point for rust and corrosion.

- Timeline & Labor Costs: What was scheduled as a rapid, assembly-line installation becomes a custom-fab logjam. Your labor costs inflate, and the project timeline is delayed, risking penalties and a missed Scheduled Commercial Operation Date (SCOD).

Long-Term Impact: The 25-Year Asset Lifecycle

The most devastating costs are those that emerge over the asset’s 25-year life.

1. Structural Failure and Accelerated Corrosion

A solar mounting structure is a 25-year asset that lives in a hostile environment. It must withstand constant exposure to UV, moisture, and high winds.

- Low-Grade Steel: This material has lower tensile strength and fatigue resistance. It is brittle and less resilient, making it susceptible to failure under cyclical wind-loading.

- Substandard Galvanization: A thin or poorly applied zinc coating will corrode and flake off in a fraction of the time of its high-grade counterpart. Rust compromises the steel, and “rust-jacking” (where rust expands) can loosen bolts and critical connections.

A structure built with these materials is not an asset; it is a liability. A single high-wind event can lead to catastrophic failure, resulting in the total loss of the panels and structures.

2. The LCOE Calculation: CAPEX Savings vs. OPEX Disaster

The financial viability of a solar plant is measured by its Levelized Cost of Energy (LCOE).

The “cheap” structure fatally undermines this calculation.

You are trading a fractional CAPEX saving (perhaps 1-2% of the total project cost) for a massive, long-term OPEX increase. This increase comes from:

- Constant repair of failed and corroded components.

- Increased downtime and associated generation loss.

- Higher insurance premiums due to the high-risk materials.

- The risk of total replacement of the structures long before the 25-year design life, a cost the project’s financial model cannot absorb.

This calculation dramatically increases your LCOE, eroding profitability and delivering a poor return to investors.

Conclusion: Procurement Must Prioritize Engineering and Reliability

A solar mounting structure is not a simple commodity. It is an engineered foundation that is fundamental to your project’s safety, output, and financial success.

Procurement departments must look beyond the initial price tag and evaluate suppliers based on their engineering capabilities, material sourcing transparency, and in-house capacity.

Ask potential suppliers to provide:

- Mill Test Certificates (MTCs) for their steel.

- Proof of design verification against your specific panel’s datasheet.

- A proven track record of on-time delivery backed by in-house production control.

A partner who leads with their engineering quality, not just their price, is investing in the long-term bankability of your project. Choosing anything less is a risk not worth taking.

Call to Action:

Don’t let a procurement shortcut become a 25-year liability. At Rudran Infra Metals, we build on a foundation of engineering excellence, using only certified, high-grade steel from India’s top mills. Contact our technical team to discuss how a guaranteed-fit, high-reliability structure lowers your project’s true cost of ownership.